Media

Videos

Corporate - Davi HQ - Power Generation Seminar 2025

On October 14–15, we had the pleasure of welcoming over 80 customers and potential partners from around the globe to our headquarters for the Power Generation Seminar 2025, an event dedicated to innovations and technologies in the Power Generation sector.

Videos

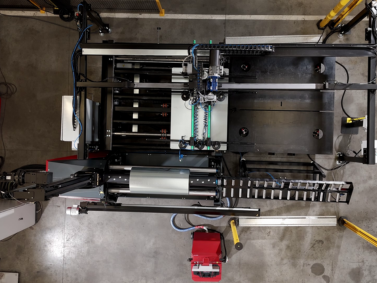

Plate Roll - MCB (4 rolls) - Assembly and disassembly timelapse - Sif Group

Watch the full timelapse of the manufacturing process of a heavy-duty MCB plate roll at Davi, designed specifically for the wind energy sector. This project was developed for our customer Sif Group, a leading player in offshore foundations for wind energy projects.

ARTICLES AND NEWS RELEASES

Davi is proud to announce the appointment of Capital Machine Technologies, Inc. as its strategic partner for the expansion in the Mid Atlantic region

Dallas, Texas – August 28, 2025 – Davi. Inc., a global leader in plate and angle roll machines, is proud to announce the appointment of Capital Machi...

Follow our newsletter