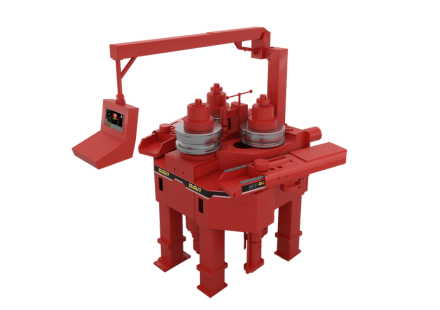

MCO – THREE ROLL DOUBLE PINCH

RANGE

The most common design in the industry, with the top roll fixed, and the two side rolls that move up and down to pre-bend the edges, and to roll the plates.

The most inexpensive roll for plates from 15-20 mm (5/8 – 3/4 inch) thickness, up to 80-100 mm (3 – 4 Inch), and more, it is recommended for limited production volumes.

Suggested applications

Other products

media

On October 14–15, we had the pleasure of welcoming over 80 customers and potential partners from around the globe to our headquarters for the Power Generation Seminar 2025, an event dedicated to innovations and technologies in the Power Generation sector.

Watch the full timelapse of the manufacturing process of a heavy-duty MCB plate roll at Davi, designed specifically for the wind energy sector. This project was developed for our customer Sif Group, a leading player in offshore foundations for wind energy projects.

Accuracy and productivity with the MCE e-POWER, the world’s first fully electric 4-roll plate roll, engineered by Davi.

With AI-Vision you can SEE BEYOND: 🧠 The skill gap: smart automation bridges operator expertise. ♻️ Material waste: zero scrap thanks to real-time corrections. ⏱️ Time loss: instant precision, no trial-and-error.

Dallas, Texas – August 28, 2025 – Davi. Inc., a global leader in plate and angle roll machines, is proud to announce the appointment of Capital Machi...

https://emo-hannover.de

https://www.fabtechexpo.com/

https://www.schweissen-schneiden.com/joining-cutting-surfacing/

Case Study: How IDESA Optimized Production with Davi Technology | Davi Plate Rolling Solution

We are glad to unveil our partnership with GS Entec for the supply of two huge plate rolling machines (equipped with all the accessories that are nee...