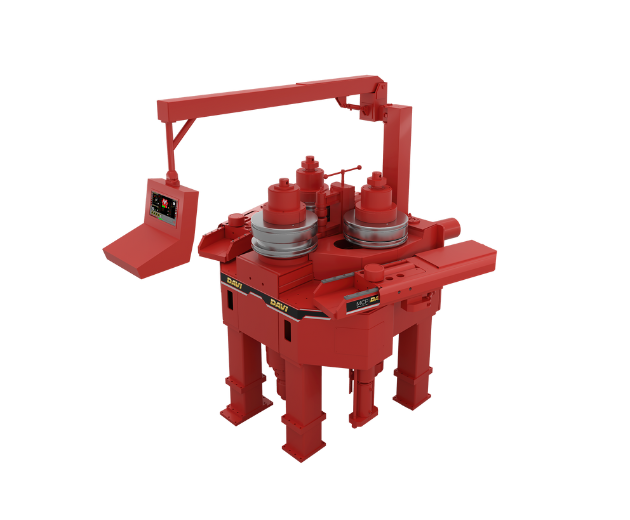

MCP

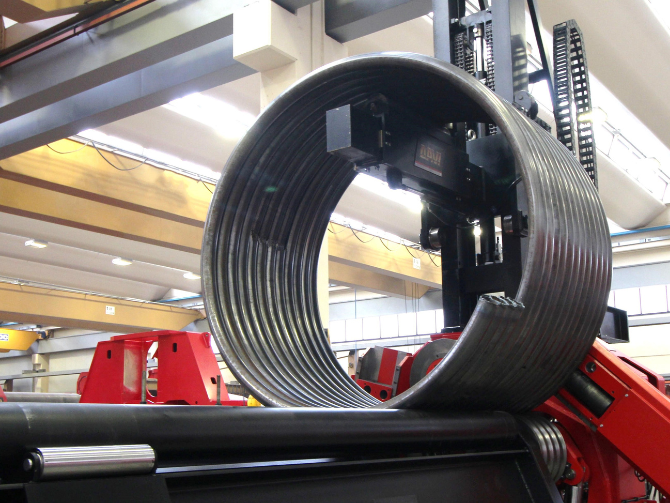

Davi MCP - 3-ROLL DOUBLE PINCH ANGLE ROLL MACHINE Because of variability in processed parts, required accuracy, output volume, etc. each industrial sector requires dedicated manufacturing strategies. When it comes to section bending, such strategies must be accommodated by selecting the right machine based on the specific application. Thanks to the wide range of available angle roll machines, Davi can offer the most suitable machine for any application. Depending on machine capacity, a 3-roll double pinch machine can operate in two different ways: with horizontal shafts: usual configuration for small machines, allowing for simpler operation due to easy handling of small sections; with vertical shafts: usual configuration for large machines, required to be able to simplify handling of heavy sections by bending them parallel to the ground. Regardless the configuration, Davi MCP 3-roll machines feature two side rolls moving against the fixed top roll. The side rolls, actuated by planetary guides technology, provide the necessary bending force achieving tight diameters per capacity while obtaining high accuracy.

Suggested applications

Other products

media

Case Study: How IDESA Optimized Production with Davi Technology | Davi Plate Rolling Solution

We are glad to unveil our partnership with GS Entec for the supply of two huge plate rolling machines (equipped with all the accessories that are nee...

Petrochemical production with advanced plate rolling - The strategic investment: why BETA chose Davi

In 2024, Davi solidified its leadership in the wind energy sector by delivering 30 complete rolling solution lines worldwide. These tailored system...