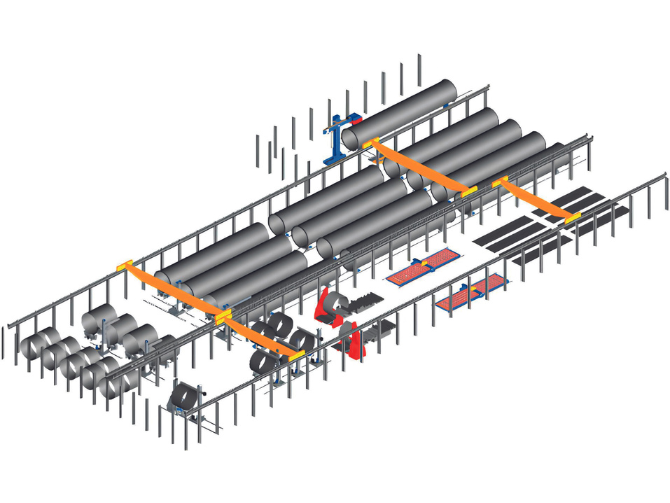

iRoll EXTREME + iCONE SOFTWARE + LASER MEASURING SYSTEM

iRoll eXtreme is the most advanced control system in the industry: an ergonomic console with a high-resolution touchscreen and a live 3D interface. It's as easy to use as a smartphone for creating programs, thanks in part to the exclusive AI.

iCone software is an exclusive software designed by Davi that allows you to manage the position of pushers and hydro-guides as the sheet is positioned and moves during processing.

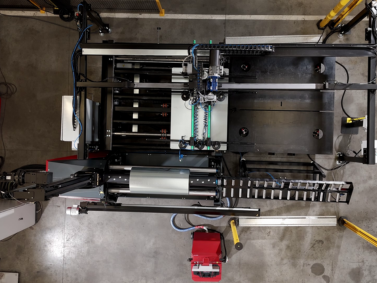

Laser measuring system: Maximum measurement accuracy.

Ability to track and record forming tolerances. Full automation thanks to seamless integration with iRoll eXtreme software.

Safer operation (operators are always kept away from trapped parts).

Real ability to operate the machine with just one operator.

Request for quote

Please, fill in the form to request a quote.