Reliable and easy-to-use Plate Roll for Tank Manufacturing and Large Casks

The history of Steel America dates back to 1875, when its parent company, Colonna’s Shipyard, Inc. established a full-service ship repair facility along the banks of the Elizabeth River in Norfolk, Virginia. In 1990, following the decision to better penetrate industrial markets, with a focus on custom steel fabrications, a new division was formed and branded as Steel America.

Since then, the company has made its path into various sectors ranging from military to marine infrastructure, industrial plants, power generation, flood control and civil projects, becoming a premier fabrication and machine shop. Thanks to their experience, expertise and equipment, they developed a unique ability to fabricate custom solutions, taking particular care of quality, timing and budget constraints.

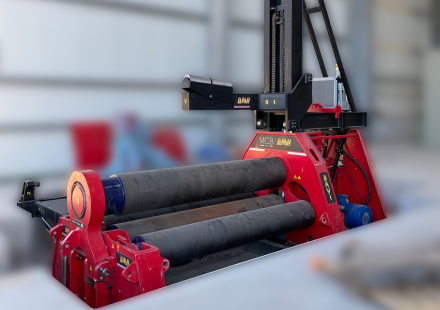

Committed to continuing its strategy of industry diversification and entrance to new markets, Steel America decided to add a DAVI Plate roll to their plant, as new markets required heavy rolling capacity. When the decision was made to add a plate rolling machine, DAVI immediately came to mind with two factors critical to the final decision, quality and reliability. Despite not having any particular needs in terms of machine customization, they were looking for a plate roll manufacturer that could assure years of reliable production.

For a company that puts so much attention on quality, cost control and time efficiency, another pivotal aspect was the easiness of operation and possibility for new employees to quickly become familiar with its use.

Since its entrance in Steel America’s production system, their DAVI MCB (10 ft. x 2" 1/8 capacity) has been challenged with different kinds of plates (Carbon Steel, Stainless, HY-80, HY-100 and HTS), allowing the company to play in new markets, such as tank manufacturing and large casks. In fact, the new plate roll machine allowed them to streamline their production process, reducing delivery time as well as outsourcing costs.

Currently, the new plate roll is involved in projects such as building Caisson Gates, and US Navy aircraft carrier and submarine modules.

On top of the customer’s satisfaction with the technical performance of the machine, the two firms developed a positive working relationship with the DAVI personnel defined as ‘helpful, courtesy and professional’, before, during and after the installation, based on responsive and detailed customer service.

These elements form a long-term relationship both parties expect to benefit from. Should the need arise for further expansion of Steel America’s plate or angle roll capabilities, both firms look forward to further collaboration. This is what we call a ‘partnership’ perspective.