Offshore Towers Features

- Height: Soaring to impressive heights of up to 120 meters (394’), offshore wind turbine towers are engineered to harness the stronger and more consistent winds found over open waters.

- Structure: Comprising 3-4 sections, these towers are designed for stability and resilience in challenging offshore conditions.

- Diameter: Ranging from 6 to 12 meters (20’ to 40’), these towers are substantial, ensuring they can support the massive turbines required for offshore wind farms.

- Thickness: With steel thicknesses between 100-120 millimeters (4”-5”), offshore towers are built to withstand the corrosive effects of saltwater and the relentless forces of the sea.

- Width: Measuring 3-4 meters (10’-13’) in width, these towers are engineered for stability, even in the face of powerful ocean winds.

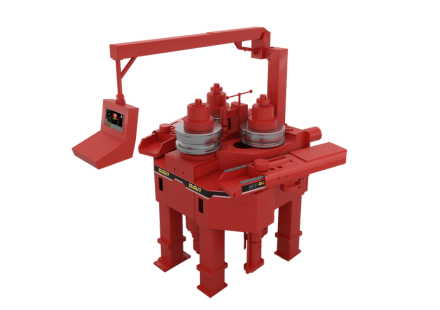

DAVI SOLUTIONS FOR OFFSHORE AND ONSHORE WIND TOWERS

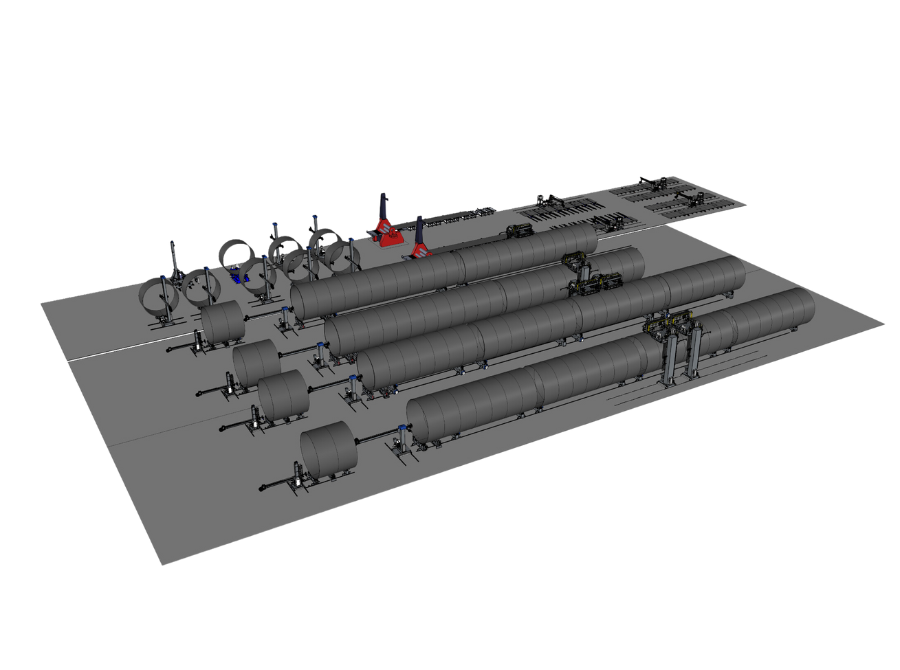

1. Wind Energy Line: Our Wind Energy Line is a comprehensive solution that combines advanced machinery with essential accessories and a feeding system. This system streamlines the tower manufacturing process, making it more efficient and precise. Davi empowers manufacturers to produce towers with accuracy and reliability, meeting the rigorous standards of the industry.

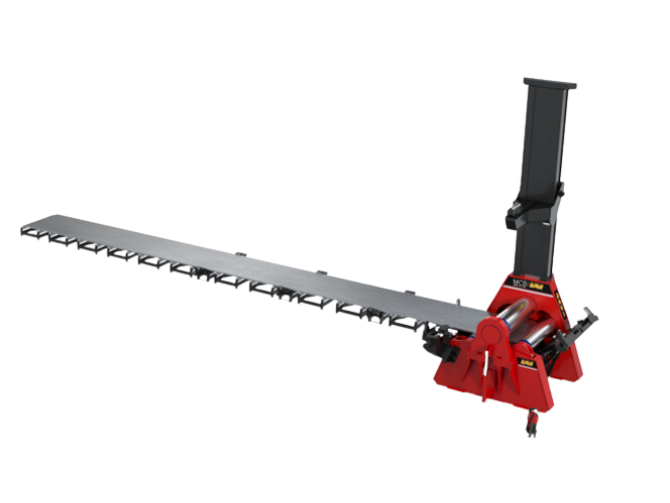

2. High Productivity Line: Davi's High Productivity Line takes tower manufacturing to the next level. This solution includes a lifting feeding system (for a safe, fast and accurate pre-bending) and incorporates intermittent plate repositioning to form the necessary cone shapes. This innovative approach significantly enhances productivity while maintaining the highest quality standards. It is ideal for meeting the demands of high-volume tower production, ensuring efficiency without compromising on precision.

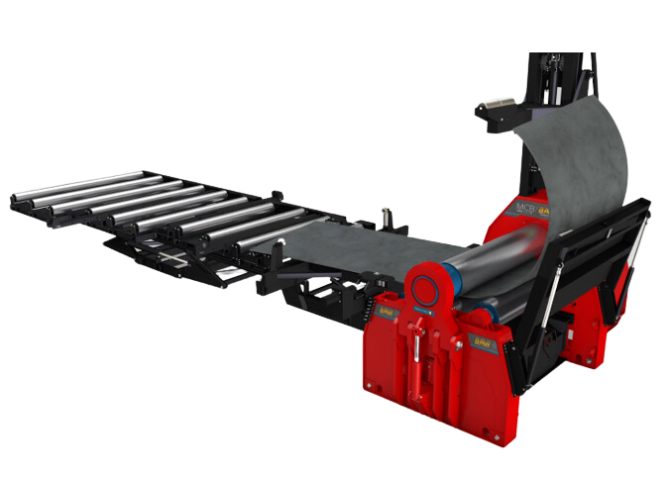

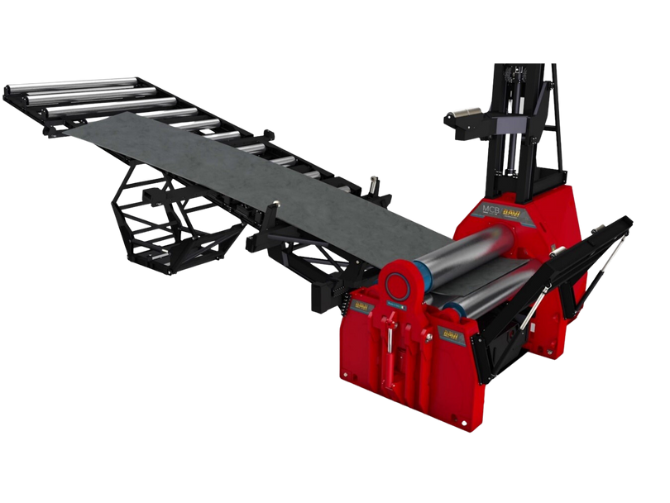

3. Smart Line: Davi's Smart Line represents the pinnacle of wind tower manufacturing technology. This solution offers continuous plate feeding, enabling the seamless formation of cones. The benefits are manifold, including faster production rates, enhanced product quality, a safer operational environment, and simplified machinery operation. The Smart Line is engineered to optimize the entire manufacturing process, from start to finish.

Other products

MEDIA

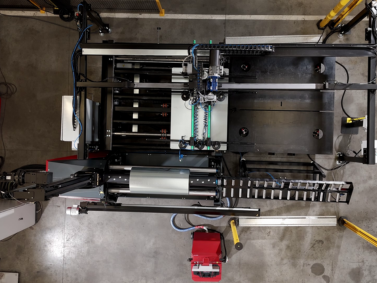

Watch the full timelapse of the manufacturing process of a heavy-duty MCB plate roll at Davi, designed specifically for the wind energy sector. This project was developed for our customer Sif Group, a leading player in offshore foundations for wind energy projects.

Accuracy and productivity with the MCE e-POWER, the world’s first fully electric 4-roll plate roll, engineered by Davi.

With AI-Vision you can SEE BEYOND: 🧠 The skill gap: smart automation bridges operator expertise. ♻️ Material waste: zero scrap thanks to real-time corrections. ⏱️ Time loss: instant precision, no trial-and-error.

https://emo-hannover.de

https://www.fabtechexpo.com/

https://www.schweissen-schneiden.com/joining-cutting-surfacing/

Case Study: How IDESA Optimized Production with Davi Technology | Davi Plate Rolling Solution

We are glad to unveil our partnership with GS Entec for the supply of two huge plate rolling machines (equipped with all the accessories that are nee...

Petrochemical production with advanced plate rolling - The strategic investment: why BETA chose Davi