Shipbuilding

The industry of shipbuilding includes a wide range of products and applications for which fabricators need various kinds of roll bending machine and angle roll. Customized machines are often requested for specific tasks and DAVI R&D has studied many special solutions in the recent years.

For cargo ships and oil tankers, the thickness of the plates to be rolled is not so relevant, since it's never more than 30/40 mm. In this case, the distinctive feature is the width of the plate rolls, that can reach 20 m.

Regarding navy ships and fishing boats, thickness stays more or less the same, varying around 30 and 40 mm. The width of the plate roll is quite standard (between 3 and 6 m), but various accessories (overhead support, side support, etc) are often required because of the peculiar shapes of the plates to be rolled.

When it comes to submarines, that are made with high resistance material, the roll bending machine is 3 or 4 m wide, but they have to be heavy duty. In fact, the plate thickness can reach 120 mm.

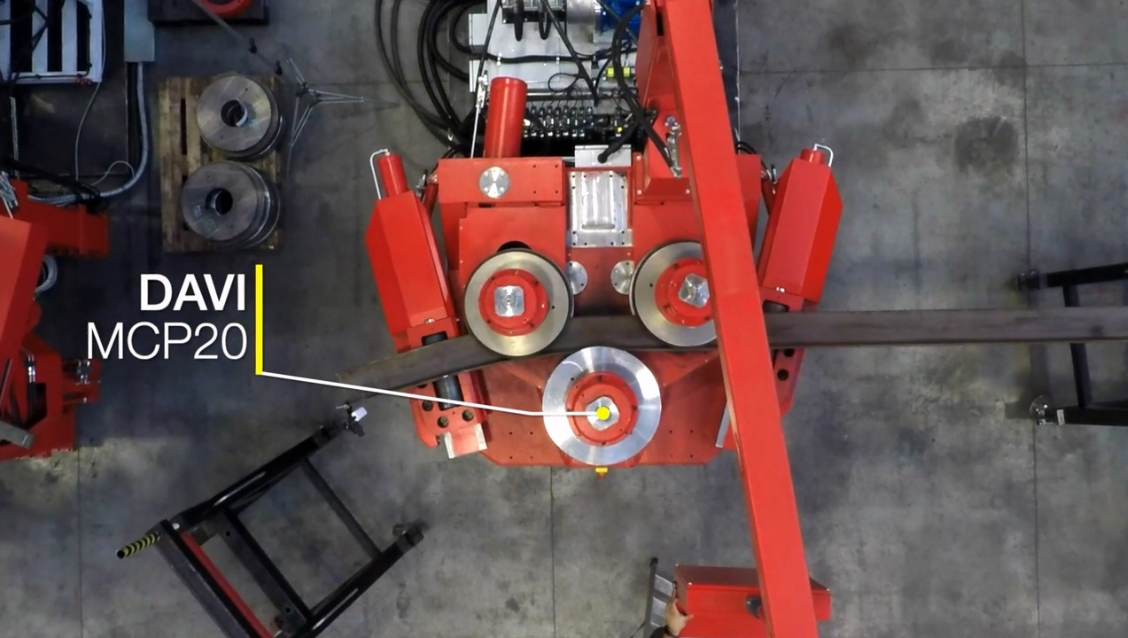

Finally, also angle roll find an application in the field of shipbuilding, since they are used for bending twin bulbs and many other sections, like the ones for stiffening components and decks.

.png)