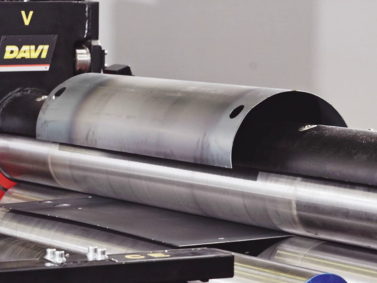

Thickness of the Plate

Machine models

1" - 2" Request for quote

2" - 3" Request for quote

3" - 4" Request for quote

4" - 6" Request for quote

6" - 8" Request for quote

8" - 12" Request for quote

12"+ Request for quote

Suggested Videos

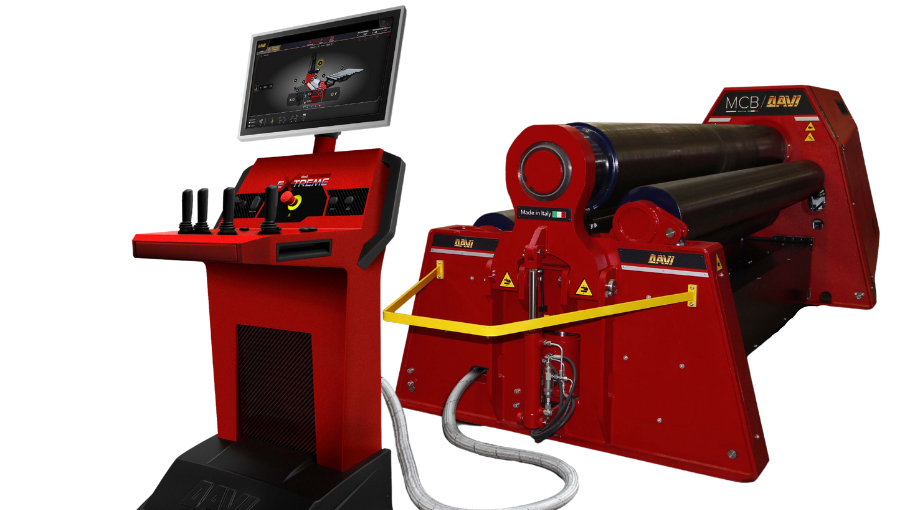

Driven by innovation, our dedicated Research & Development Division is constantly pushing the boundaries of technology to develop customized solutions and address the unique challenges of our customers. We take great pride in our ability to deliver tailored machines that ensure superior performance, efficiency, and productivity.

.png)

.png)